- A bit of background

- The Diagnosis

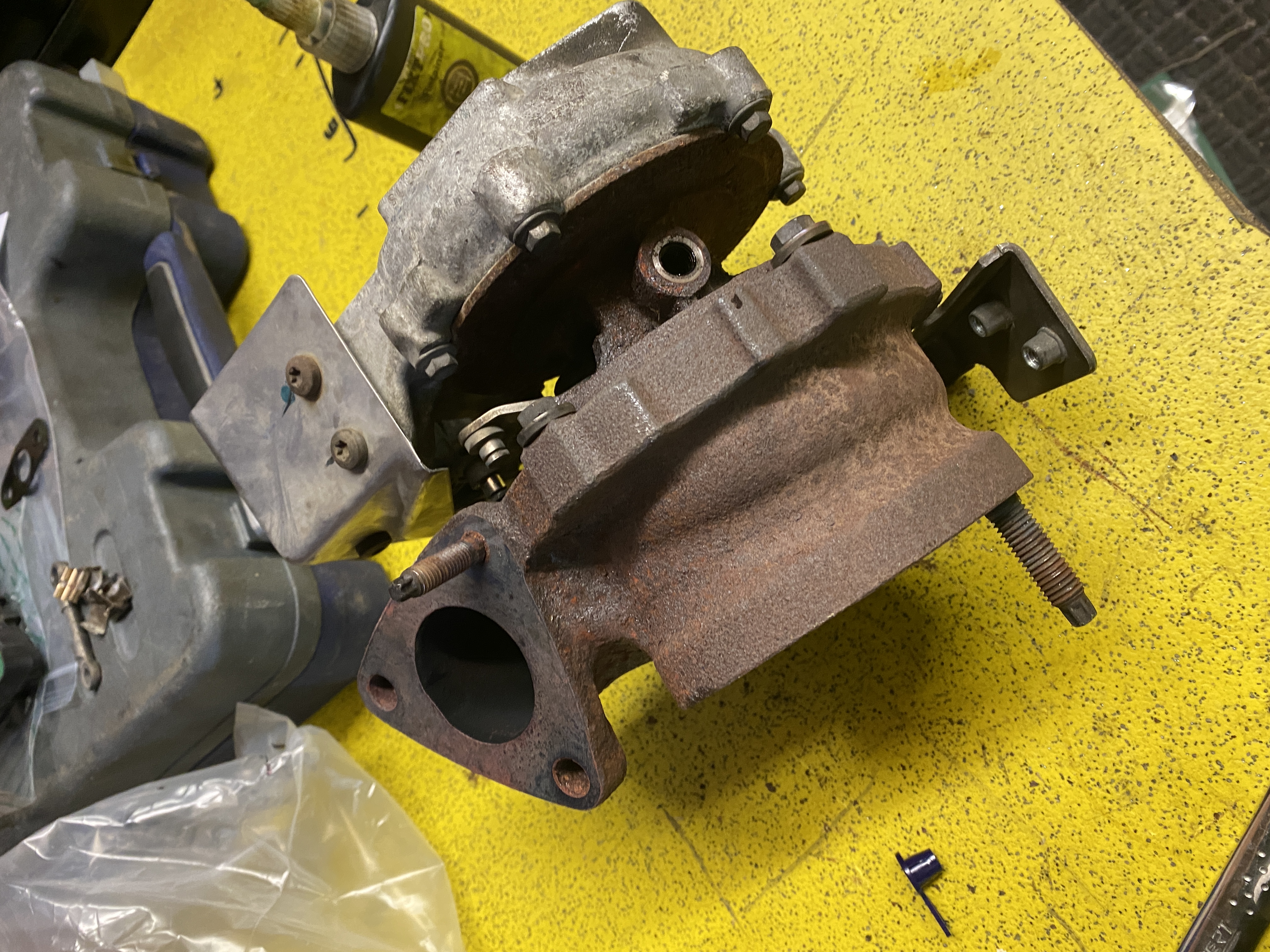

- Replacement of turbo

- The P0299 Underboost fault

- Heres what we went through trying to get to the bottom of this.

- A few odd pics

- Some useful part numbers;

- Has it been fixed yet (a list of people that have emailed me ref this)

- A very good suggestion for a possible fix

- Person 12 – Initials JT 29/10/23 (Fixed their one)

Completely unrelated – Need a key blade only for your Ford? Read here

A bit of background

Now this is a story all about how, My life got flipped turned upside down, And I’d like to take a minute, just sit right there, I’ll tell you how I became the owner of a fault called P0299.

And if your not humming the theme tune of The Fresh Prince Of Bel Air then you probably wasn’t born in the 80s, raised in the 90s. Thats enough of references to songs and down to a Transit that caused a a bit of grief; although not fixed at this stage, I will update the post when it is. However this may be worth a read as many people seem to have come across this fault symptoms / codes with various fixes – one may solve your issue (I assume thats how you ended up here!). I also believe i know where the fault lies, but its beyond my capabilities / knowledge with Fords so referred it to a dealer.

The Ford Transit in question is 2015 Minibus, 2.2 Diesel, RWD, Euro 6 spec (With adblue). The fault started when a message appeared on the instrument cluster “Engine Service Now”. Then engine would barely go above 1500 RPM, could just about limp it on this to pull over and recycle the ignition. Once this was done, it seemed to clear but as you tried to drive it, the same thing happened again.

The Diagnosis

We read out the faults; P2598-00 ‘Turbocharger Boost Control Position Sensor “A” Performance & P0299-00 ‘Turbo underboost condition. We did attempt clearing the faults and road testing but naturally the fault occurred before we could get a few meters. Only the boost control position sensor fault returned. We can only assume underboost due to turbo issue at this point.

Given the fault codes in memory, symptoms & the returning fault code for boost control it was clear that we was looking at a turbo issue, so proceeded to check all the relevant wiring for any visual defects / chafing – nothing to be found. (Various sources have told me that it is common for the wiring to rub behind the alternator.)

We removed the turbo, removed the rod from the electric actuator, checked that the lever for the VNT / wastegate was operating OK – all good. (Again, various sources have said that it can get carbon build up and stop it moving).

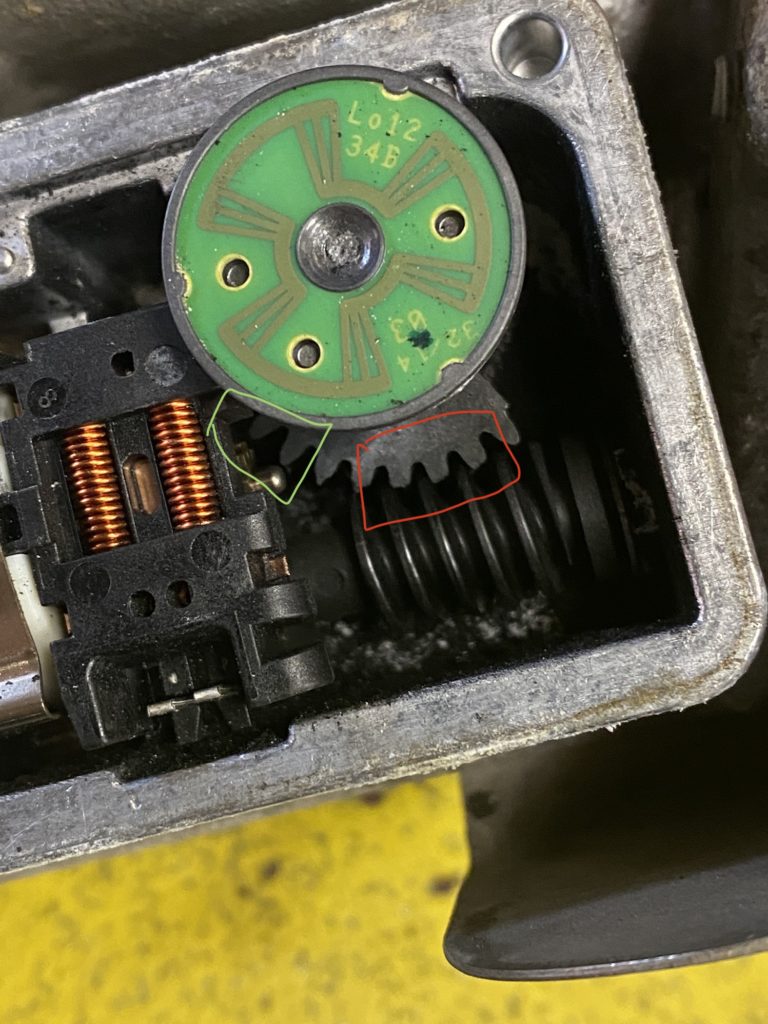

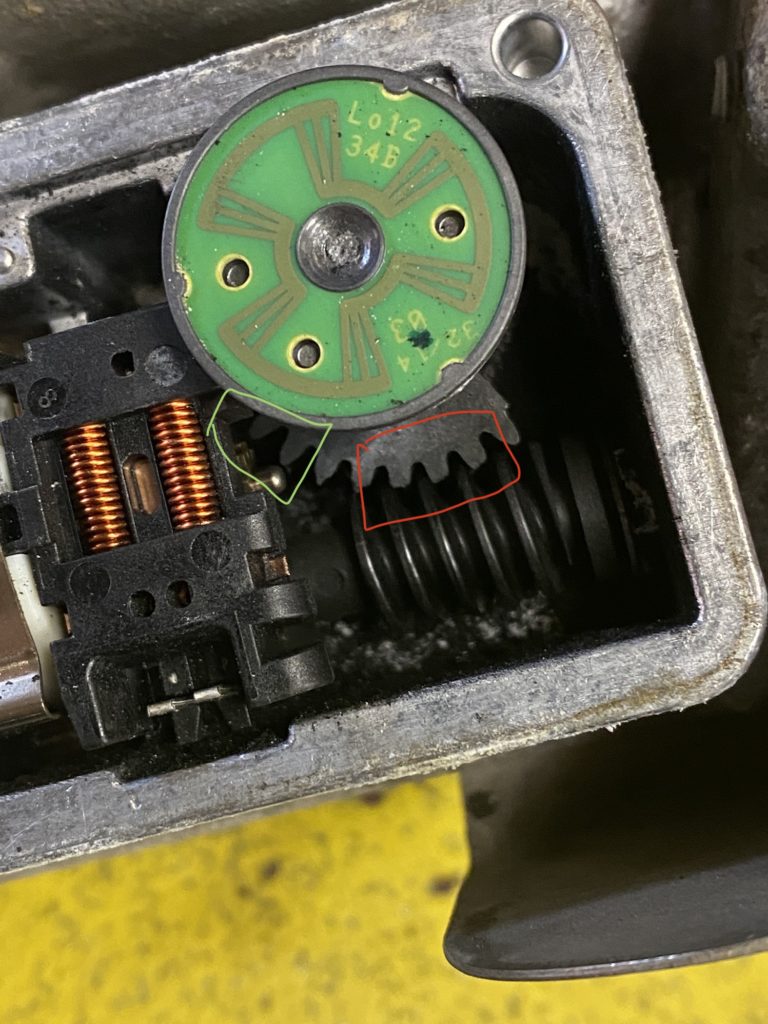

Next we removed the cover for electric actuator on the turbo – we found that the plastic gears had worn away. We manually powered the motor inside the unit, when actuator motor worm drive rotates, the gear skips against it. At this stage it was pretty clear that a replacement turbo / actuator was needed.

Ford do not sell the actuator separately, only as a whole turbo. There are various places that can remanufacture the electric actuators, however, as this is a normally in use most of the time a complete turbo was the best route. Wouldn’t be good for the turbo to suffer failure after all this!

Replacement of turbo

The turbo was replaced. Without getting into the nitty gritty of this particular job, its fairly straight forward, (For the RWD ones at least.)

Air intake pipe, aux belt cover, aux belt, alternator have to come off for access then its not to bad to do. A few awkward bolts, oil feed pipe is a bit awkward too…

All relevant gaskets and seals replaced.

Oil feed pipe removed and checked clear.

Oil and filter renewed / air filter renewed for warranty purposes.

The P0299 Underboost fault

So happy days, turbo replaced and smiles all rou… On road test, intermittently getting P0299 Underboost. Vehicle goes into limp mode, with ignition reset, is OK. FML

Generally fault does not occur when driving hard / at higher revs.

Throughout the hole of the below situation, which incurred approx 20 hours of working on it, the more the van was driven, the longer it took for the fault to occur.

Heres what we went through trying to get to the bottom of this.

First and foremost as we was showing a underboost, the possibility of loosing air in the air intake system through a leak had to be eliminated;

– Carried out smoke test on air intake system. No leaks found

– Removed air intake pipes and inspected. We did find that the boost pipe on the passenger side was rubbing through to the cords on the chassis. This was replaced. (Apparently common)

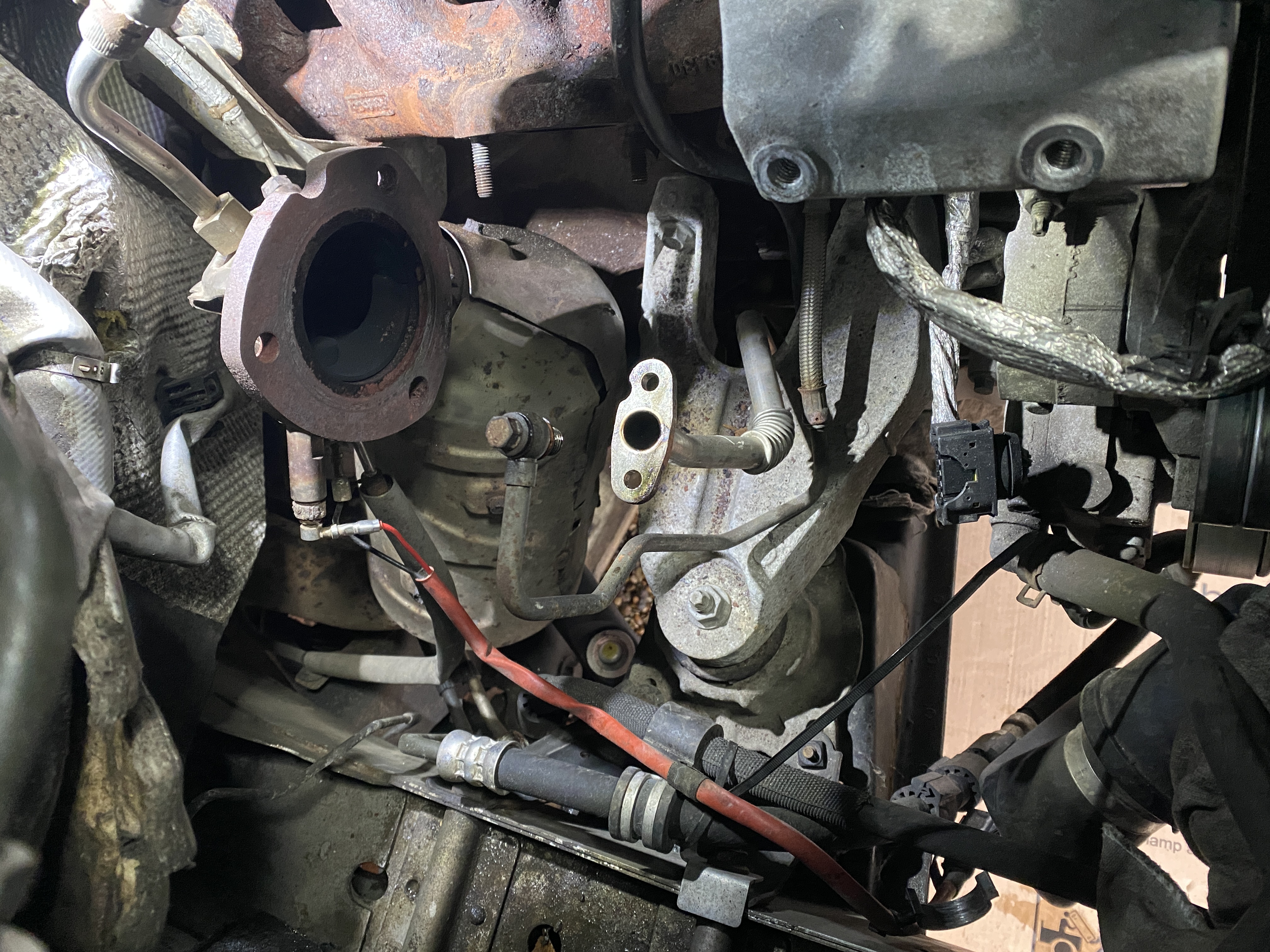

– Replaced EGR valve, we suspected it may be stuck open. It wasn’t, however it was seized closed, SOLID with carbon, even inside the electric part of it! (Also apparently very common)

Ps. Replacing the EGR valve on a RWD is a complete pig of a job (well just one bolt is a pain to get to) but I’m unhappy to confirm that you should be able to complete it on the floor with two people. FWD is very easy to do on the other hand.

Ps. Replacing the boost pipe from intercooler to throttle is also a complete pig on a RWD. The throttle area is almost inaccessible, making the pipe clip a nightmare to get back on.

As we felt we had eliminated all leaks, we thought maybe that there is an issue with the turbo not producing enough boost. Maybe the actuator needs calibrating, or maybe not even set up right. Many people have said that non genuine units can be crappy and not set up right. The unit we have is not genuine however read on as I’m sure its not at fault.

After more research, we discovered that there is a relearn procedure when the turbo is replaced. Although not setting my heart on fixing it, we needed to rule this out. We purchased a OBDLINK EX FORScan OBD Adapter, which can be used in conjunction with a piece of software called ‘FORscan’ that can carry out this procedure. Most good diagnostic machines (not basic code readers) can also do this to if you have one. There are also other OBD adaptors that can do this.

We attempted this learn procedure but just get an error back saying requirements not met. It doesn’t say what the requirements are that are not being met which is a pain. For example in my experience Mercedes, the battery voltage must be above a certain threshold, wipers must be off, doors closed etc.

Having spoke to a few people, battery voltage was said to have to be over 12v, but nothing else known of. We eliminated this by putting a battery supply unit on it but still no success. It was suggested that the values of the turbo position that the ECU was reading could be incorrect and therefore the “requirements where not met”:

Fortunately, or unfortunately, another Transit from that fleet with exactly the same engine although it be a FWD was waiting for a new turbo due to mechanical failure of the bearings. We plugged FORscan on this one and tried the relearn procedure – straight away it completed. Our theory here being, plug the old turbo unit from this into the one we have been having trouble with. If the procedure completes, we must be looking at a faulty turbo / actuator.

We tried this, but it wouldn’t complete. We compared turbo related actual values, with the replacement turbo and the turbo that was dead mechanically, all exactly the same readings. At this stage I’m convinced that the new turbo is not faulty and the underboost fault must of been a pre existing fault. Given that we can only get it to occur at very intermittent times, mainly when not under much load – maybe it just had never been experienced. Who knows!

Honestly now I’m getting pretty stumped. I can only think that maybe another sensor is giving a bad reading and somehow affecting the boost readings / calculations. Various googling, facebooking and asking a Ford tech; later;

– Checked boost pressure / MAP sensor. Make sure that with the engine off, the reading is atmospheric value. These are known to give bad readings which will affect boost readings. Have also been told that there is no separate atmospheric pressure sensor on this, it uses the boost pressure sensor – if it is showing a reading below the expected range, it will not produce a fault as they have been removed from its programming. (so im told!)

– For good measure, took a boost pressure sensor from another van on fleet and tried too.

– Checked air inlet temp sensors, same again with engine off, ensure not reading silly values! Also known to affect boost readings. Note that there are a few readings for this, one part of the air mass sensor and one in the passenger side boost pipe. (Boost pipe one mega common to give poor reading)

– Checked exhaust temp sensors – all OK.

Only unusual value that we can find is mass air flow sensor showing 2.77g/s when engine is off. (desired actual value spec is 0g/s). Again we have tried a replacement air mass from another transit and relearned, but still showing same values. We have rechecked all obvious points in loom for rubbing in case of wiring issue but unable to find an obvious issue.

We suspect that the turbo relearn procedure will not complete due to a secondary fault with the van – most likely due to the issue with the MAF reading (if there is a reading showing then it must think air is flowing therefore engine not off which is required for learn) & this is affecting a boost calculation and generating the underboost fault.

My best educated guess would be a wiring related problem and or maybe water ingress into the engine ECU.

The ECU plugs need to have some sheer bolts grinded off to get access, it is wet in that area as it is a water run off area, but we had to call it a day and advise it goes to Ford.

Ive since been told by another garage owner that water ingress into the engine ECU / plug can be an issue and they have had TWO with these symptoms / fault codes and water into engine ECU.

Watch this space, when i know, i will update!

A few odd pics

Some useful part numbers;

2019954 – Boost pipe from turbo to intercooler

1835009 – EGR Valve (Front and rear wheel drive the same units)

1763294 – Gasket from EGR unit to EGR Cooler

1758593 – Gasket from EGR unit to pipe that goes to inlet

2168125 – Boost pipe from intercooler to throttle body (comes in two parts in aftermarket)

2006019 – Air charge temperature sensor

1516668 – Air mass sensor / inlet temp sensor

1913600 – MAP (Boost) Sensor

1880424 – Air filter element

1945831 – Air filter element (small one in top of airbox)

1763292 – Turbo oil feed pipe

1331076 – Turbo Oil return pipe gasket

5206816 – Nuts that secure turbo to manifold

2024683 – Studs that hold turbo to manifold

1381962 – Nut for downpipes to turbo (need 1)

1865442 – Stud for downpipe to turbo (need 1)

1862098 – Bolt for downpipes to turbo (need 2)

In light of Person 12 below, Pierburg EGR Valve;

Has it been fixed yet (a list of people that have emailed me ref this)

- 1. No. Days elapsed, 16.

- 2. 16/07/2022

– Another garage has had this motor for a few weeks – no joy.

– Various people have messaged me on facebook asking if it has been fixed as they have the exact same scenario.

One guy says its ‘been fixed’ – buy some dude with a laptop charging a few hundred quid. Sounds like they have deleted the fault code from the software or something along them lines. ‘fixed you say….’

3. 12/04/23 – I think I’m up to 7 people have messaged me about this now, same scenario.

4. 15/05/23 – Another email

This below section is for me to keep track of all the people that have messaged me about this. Fear not, you are not alone.

– Person 1 to 6. (deleted the emails)

– Person 7. Initials CM -11/04/23

– Person 8. Initials IR – 15/05/23

– – This chap has a very good potential solution, i quote;

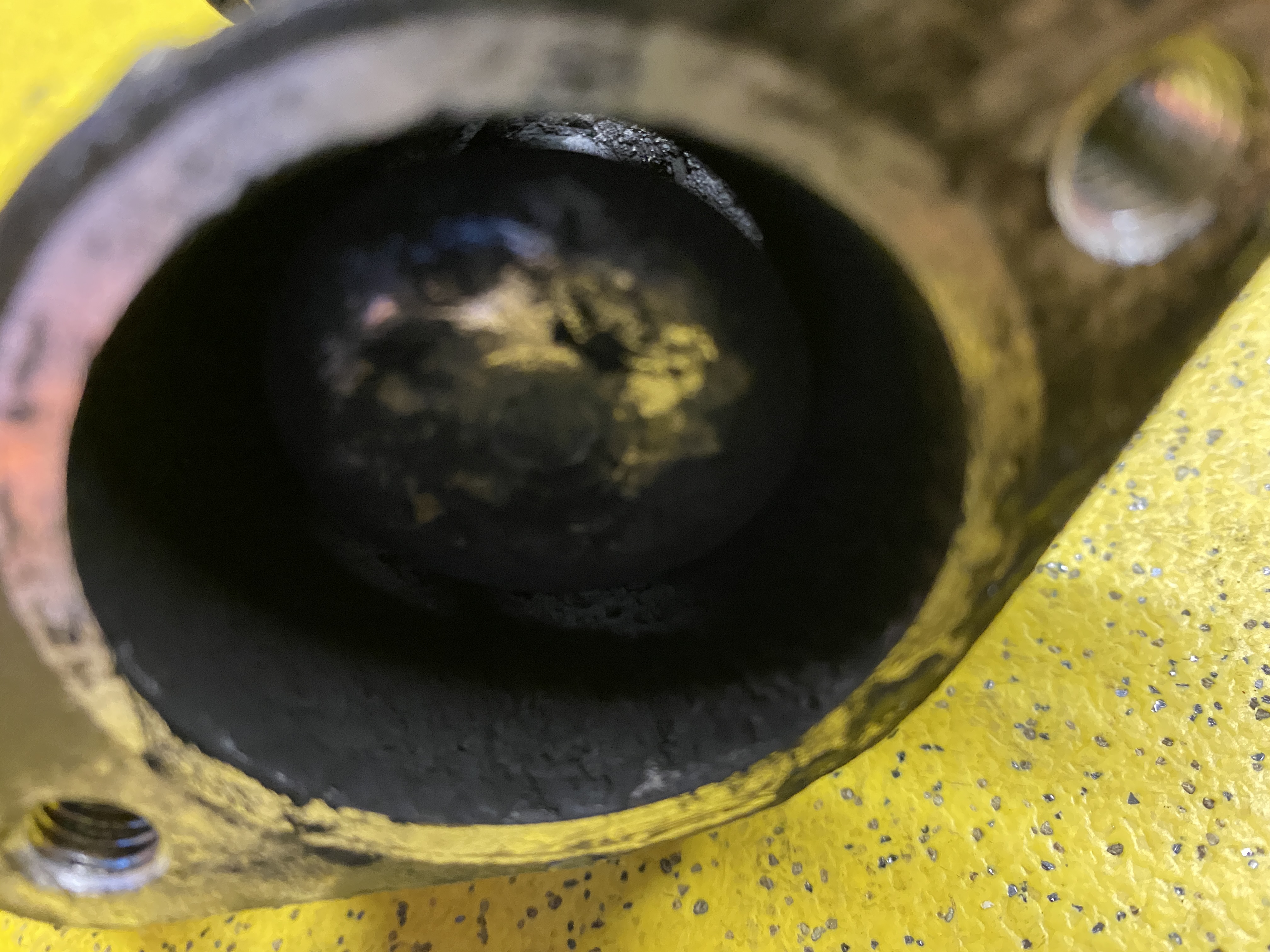

– – “On your list of things, you replaced you don’t mention which I’m told is 95% the fix(not on ours 😕) is remove the map sensor from inlet manifold and use a small piece of wire and inside where map sensor sits in manifold clean out the carbon build up and make sure is clear. There a 90-degree bend in there so make sure you get right in there. Or as we have done is replace inlet manifold. They are readily available from factors and not that expensive. That’s will cause this issue”

– – I can see exactly how this would cause the issue, i would recommend any one to check this. It may even fix this one that is at the other garage – i will update as soon as i know.

– – Ps, anyone reading this, if this fixes yours, please let me know.

– Person 9. Initials MH – 24/07/23

– – In at the deep end in with this fault since fitting new (brand new engine).

– – All the following replaced; -all new- Turbo and control unit. DPF/ Cat unit. All sensors in exhaust. MAF sensor. Map sensor. Inlet manifold. EGR. Throttle body. Temp sensor in turbo pressure pipe. Injectors ( it has done 440k km) Intercooler. ECU been changed with another. Think thats it. Exhaust been disconnected to check not blocked.

– Person 10. Initials AM – 27/07/23

– – Similar problems and going down the same path.

– Person 11 Initials GN 24/08/23

– – ‘yep..changed everything, no cigar. You’ve got another follower hoping for some progress.’

– Person 12 Initials JT 29/10/23

– – They have fixed theirs, see the whole email story / trail below

A very good suggestion for a possible fix

This section is here so my contents table updated. See above person 8!

Person 12 – Initials JT 29/10/23 (Fixed their one)

This person has fixed theirs! Here’s the email trail (oldest email at the bottom…)

Hi James,

Thought you might like to know but finally sorted the hesitation between 1500 and 2000RPM.

The work carried out to get here was:-

Checked for air leaks on turbo pipes and intercooler – all ok

Removed the 4 injectors and had them tested at a Bosch agent – all fine and in spec

Changed the MAF sensor again.

Changed the MAP sensor

The EGR valve was changed for an OEM part made by Hella (although the original was Pierburg), cost was the same at £140 odd

Brought laptop and VCM2 with 12 month licence to FDRS and IDS.

Getting fed up with all of this booked van into Ford dealers and they updated the firmware on the PCM and another module but could not diagnose the fault and had not seen it before. They wanted more time on it but £133 an hour I thought I would have another bash myself.

Ok so looking at data logger in IDS monitoring various things the one that stood out was the EGR valve which overshot when the valve was opened from fully closed. Typically overshooting the demand by 30 – 40% this seemed to coincide with the hesitation and always occurred in the 1500-2000RPM range.

For some reason neither the Ford IDS system or FDRS gave options to monitor the individual RPM contributions of each cylinder but Forscan does. Using Forscan it then became obvious that the EGR erroneous opening was exactly when RPM drops occurred on one of the cylinders. This drop was random across the cylinders so pointing to the valve.

So in summary ordered a Pierburg EGR valve from Autodoc and went through the usual agony swapping it over again. Couple of runs later and the issue has now gone and the data logger has shown that the demand and actual are pretty much spot on with very small overshoot of about 8% from fully closed to demanded position with rapid recovery to demand value. I have not reset learned values yet but would think this will remove any further residual error. Overshoot is usually the result of a second order under damped system and I would expect a small amount to always be present.

Regards,

John

From: James Cooke [mailto:email@jamescooke.me.uk]

Sent: 07 November 2023 21:10

To: John Turner

Subject: Re: Ford transit 2.2 litre 2016

Hey,

Sorry for the late reply!

Never got to the bottom im afraid. So many emails from people such as yourself with basically same problem!

I echo what you say with changing the EGR, NEVER AGAIN!!

Have you checked the inlet manifold boost pressure sensor air inlet (ie inside the manifold) is not blocked internally?

I think your on the right track, with the low boost not being true as such. (as was prob the case with the one i had).

There must be a sensor that gives a value that goes on to calculate a value for another reading, and its chucking it all out of spec. (the EGR also may be saying its open, may be as a result of this calculation?! but its not if you get what i mean, especially as its got a new unit)

I can only wish you all the best luck, and would love to know if you fix it!

Regards,

James

John Turner wrote on 29/10/2023 06:36:

Hi James, Read your blogg on Ford Transit 2.2 lktre issues and we have similar problem, wondered if you or anyone else had found a solution?In our case the vehicle is a 2016 2.2litre 17 seat minibus converted to camper van. It only has 33K miles on clock and 800 odd hours on engine so not much use.We had occasional misfires which were present from what we can remember from purchase in 2020 but these got significantly worse when we had the engine re-tuned a few months ago following completion of camper conversion. On several occasions the misfires ended up in limp mode and SERVICE NOW message but no mil light. Key-off-on cleared service message and van drove ok again for a short while.Using Forscan during one trip capturing live data and going into limp mode obtained DTC similar to yours with low Turbo boost.Because we did not have the limp mode issue before the engine tune I put the original map back onto the PCM module and we were now back to the occasional misfire.So following similar route to yourself checked the following:-Turbo hoses – no splits or damage and carried out low pressure air test on each hose which showed no issues. The hose you had a problem with had been fitted with a braided sleeve and where it went over crossmemeber a block of rubber had been fitted so obvious factory modification on later vehicles.Replaced air filters although old were like new.The existing EGR valve appeared to have large errors between demand and actual so replaced that, never again what a nightmare………..That resulted in the engine hunting at idle as the valve kept cycling (viewed on ForScan). Carried out re-learn on EGR valve and after similar hunting when cold settled down to run quite smooth. Test drive still gave occasional misfire but significantly reduced.I have attached extract from Forscan logging carried out at the time which showed the EGR opening despite the desired command being low or zero and at the same time the MAF sensor indicating a much lower air flow than that demanded again by a significant amount. These situations all appeared around or on the time when misfire occurred.Changed the MAF sensor, carried out re-learn but that made no difference so the old one was re-fitted.So my thoughts are that perhaps the low turbo boost could be a misleader and because the wide variation occurs in mass air flow requested and that supplied due to EGR opening the PCM thinks that the turbo cannot provide sufficient boost?Running out of ideas here ……Thanks,John